HOW TO REPAIR CONCRETE WITH MABI INJECTORS AND EPOXY RESIN?

If you need to fix structural cracks in the foundation or basement walls, epoxy crack injection is likely the best solution. This method can restore the structural integrity of the damaged concrete, and the results are long-lasting. But before getting started, it is essential to take into account the following:

Is the crack active or dormant?

Active cracks may experience movement or change, whereas dormant cracks will no longer change size or shape. Due to the rigidity of cured epoxy, it is best when used on dormant cracks.

How big is the crack?

Epoxy injection is ideal for cracks that are ¼” or smaller in width. While you can use epoxy resin to repair larger cracks, other methods and materials may be better suited.

How much moisture is present?

If too much moisture is present, the epoxy may not adhere to the concrete properly. If the epoxy does not adhere correctly, this may compromise the effectiveness and durability of the repair.

*If the crack is actively leaking water or the surrounding area is consistently moist, you must address this first. Most normal epoxy resins are unable to adhere to and fill the crack. Although there are special epoxies designed to react and bond to damp surfaces, other chemical resins may be more effective.

Benefits of MABI Injectors

Made of resistant, high-quality plastic, MABI injection packers are perfect for low to medium pressure injections. With the various fittings molded directly onto the injector, their streamlined design is an ideal solution for concrete repair contractors.

WHAT IS EPOXY RESIN?

Epoxy resin is a 2 component chemical product that consists of a resin and a hardener. When mixed, a chemical reaction occurs, which causes the epoxy to harden and cure into a durable material. Epoxy resin is ideal for concrete crack repair due to its excellent bonding properties and ability to fill and seal even the narrowest cracks.

Various types of epoxy resins are available; however, for concrete crack repair, you’ll typically use low-viscosity or ultra-low-viscosity epoxies. These lower viscosities are preferred because they can flow easily into narrow cracks and provide complete penetration and bonding. It is essential to choose a high-quality epoxy that meets the specific needs of your concrete repair job.

If you are not a specialized epoxy injection, we recommend contacting an experienced contractor to ensure the repair is performed properly.

The Epoxy Injection Method

Before beginning the epoxy crack injection method, you will choose one of two types of equipment: surface ports and injection ports. When the crack is visible (not too deep) and accessible from the surface, or when drilling can damage the structure, you will want to use surface ports. If the opposite is true, you will use injection packers. In either case, the steps involved are similar.

Here is how to perform the epoxy crack injection method using MABI injectors:

Step 1: Examine the crack

Identify its source, location, and extent to choose the best repair method.

Step 2: Prepare the crack

Clean the surface and interior using a wire brush or compressed air. This step will remove dust or debris and ensure the epoxy resin can bond properly with the concrete. Apply an epoxy putty on the crack surface to prevent the injection resin from leaking during injection.

Step 3: Drill holes

If using injection packers, you will now drill holes at intervals along the length of the crack. To determine how far apart to space the injectors, divide the thickness of the structural element by 2. For example: 12 in. wall → 12/2 = 6 in. Drill holes at a 45° angle. The drill holes should intersect the crack at the midpoint of its depth. (Holes should also be cleaned prior to inserting the injectors to ensure maximum adhesion.)

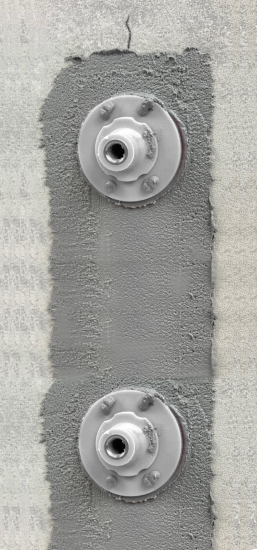

Step 4: Insert injectors

To install MABI injectors, use a hammer and a mounting tool to drive injection ports into the drill holes.

Step 5: Inject epoxy

Mix your epoxy resin according to the manufacturer’s instructions. Use the correct coupler and connect your injection gun to the injector head. Begin injecting from the bottom up until the crack fills with epoxy.

Step 6: Wait for epoxy to cure

This step is essential. Do not remove the injectors until the epoxy has fully cured. Premature removal of the injectors may result in an improper repair.

Step 7: Remove injection ports and epoxy putty

Once the epoxy cures, remove the injectors and the epoxy putty. If using MABI injection ports, save time by simply cutting off the injector head. Being made of plastic, MABI injectors won’t rust so there’s no need to worry about damaging the structural element.

If using surface ports, steps 3 – 5 will change slightly.

Here is how those steps change:

Step 3: Install surface ports. Before executing this step, you need to be sure that the surface of the concrete is dry. Place the surface ports along the crack at regular intervals. Use an adhesive epoxy to mount the ports onto the crack.

*A moist surface will weaken the bond between the surface port and the adhesive epoxy used to glue the ports. If a surface port is poorly attached, it may not withstand the injection pressure.

Step 4: Fill the space. Cover the surface space between each surface port using an epoxy putty. This step will ensure the epoxy stays in place during curing.

Step 5: Inject epoxy. Inject your epoxy resin through the surface port following the manufacturer’s instructions. Like with injection ports, you will start injecting from the bottom up for vertical cracks and from one side to the other for horizontal cracks.

Following step 5, you may continue with the final steps of the injection process described above.

If you have additional questions about MABI injection ports for concrete repair you can learn about the system here.

To order MABI injection packers become a US distributor, contact us.